OPTIMISING PRODUCT HANDLING AND ACHIEVING HIGH PRODUCTION CAPACITIES

Lanfranchi Group

Lanfranchi Group è un’azienda leader nel settore dell’imbottigliamento.

Dal 1980 creiamo e progettiamo linee adatte ad ogni tipologia di contenitore plastico.

OPTIMISING PRODUCT HANDLING AND ACHIEVING HIGH PRODUCTION CAPACITIES

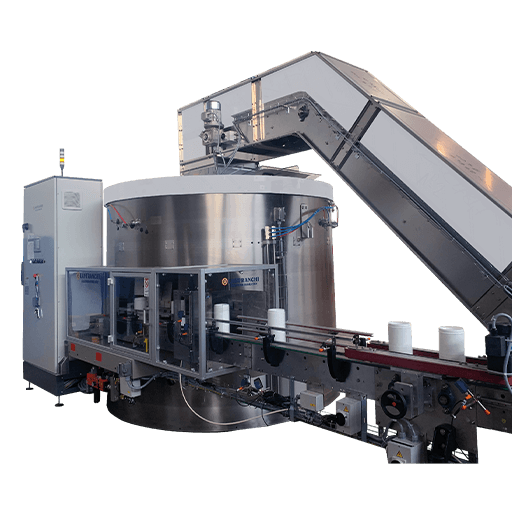

The technological leadership of Lanfranchi Unscramblers is based on numerous patents aimed at optimising product handling and in meeting very high production rates with unmatched efficiency.

Thanks to a vast range of standard machines, Lanfranchi offers the right solution for all processing needs. All Lanfranchi unscramblers can be upgraded to meet the strict cleaning and hygiene specifications required by the pharmaceutical industry.

The Classic unscrambler is mainly suited for medium/large sized bottles.

The containers slide gently onto a fixed stainless-steel cone and are positioned on the circumference of the unscrambler.

From here, containers are selected by Lifters (Lift Master patent) that convey them smoothly to the upper part of the unscrambler. In this way the bottles avoid being re-scrambled and knocked about due to the high relative velocities typical of other technologies. The efficiency of the unscrambler is further increased by the bottle extractor systems (in most cases without stopping the machine) that remove any damaged bottles that are conveyed to the unscrambler.

Compact is suited for bottles with a maximum height of 270 mm. Especially suitable for beverages, yogurt, foodstuffs, dairy, juices and detergents.

The containers slide gently onto a fixed stainless-steel cone and are positioned on the circumference of the unscrambler.

From here, containers are selected by Lifters (Lift Master patent) that convey them smoothly to the upper part of the unscrambler. In this way the bottles avoid being re-scrambled and knocked about due to the high relative velocities typical of other technologies. The efficiency of the unscrambler is further increased by the bottle extractor systems (in most cases without stopping the machine) that remove any damaged bottles that are conveyed to the unscrambler.

Lanfranchi Unscramblers for special applications have been designed to process special jars, cans, containers or bottles that are difficult, if not impossible, to process with standard technology.

The Lanfranchi robotized unscrambler represents a revolutionary innovation in plastic container handling. Format change is fast, lasting about 3 minutes. The robotized unscrambler does not need any additional external container orientation system. Thanks to suitable lighting of the feed conveyor belt, the cameras read container orientation and position. The vision system sends the pick signal to the Robots through the Pick Master tracking software for synchronization.

Format change is completely automatic and is carried out by the operator through the three commands described below:

The system can handle different formats through the creation of a specific menu for each new format.

The menu can be provided directly by Lanfranchi or developed by the Customer after a training course provided by a Lanfranchi engineer.

Technical characteristics of the Lanfranchi robotized system:

Thanks to the Unscrambler 2.0 it is possible to increase the efficiency of the production lines by performing a format change in a very short time without the presence of an operator.

The Lanfranchi ECO unscrambler is ideal for low speeds. Suitable for all types of PET and HDPE containers. ECO is a range of compact machines for low and medium speeds and at a contained cost, able to maintain the same level of technical efficiency and quality of high performance machines. All of the parts touching the product are stainless steel. The facility of visual control and access to the various machine parts was prioritized. Format change is easy to perform. The overall footprint is reduced. The main motor, that of the elevator belt and outfeed table-top conveyor belt, is always controlled by the frequency inverter to allow a careful regulation of its functioning.

YOUR ENQUIRY

Please use this form to enquire further information: