A SOLUTION CHARACTERISED BY AN EFFICIENT CONTAINER AIR CLEANING SYSTEM

Lanfranchi Group

Lanfranchi Group è un’azienda leader nel settore dell’imbottigliamento.

Dal 1980 creiamo e progettiamo linee adatte ad ogni tipologia di contenitore plastico.

Lanfranchi Group è un’azienda leader nel settore dell’imbottigliamento.

Dal 1980 creiamo e progettiamo linee adatte ad ogni tipologia di contenitore plastico.

A SOLUTION CHARACTERISED BY AN EFFICIENT CONTAINER AIR CLEANING SYSTEM

We are particularly attentive to customer needs who, because of the products being filled, cannot rinse the containers with liquids.

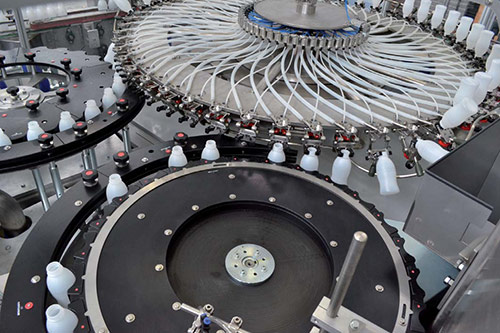

This is what Air Rinser was created for. It directly feeds a strong jet of air into the container, exploiting the feature of high penetration of the Lanfranchi injection system. As the air flows out, it carries the impurities with it.

The blowing turret of rotary air rinsersare manufactured with high quality material and technical solutions, that give a modern aspect and make them clean and practical.

The mechanical parts in touch with the bottles and rinsing air, such as grippers, the plug valve, etc. are manufactured in stainless steel aisi316 or plastic.

Some parts are made in plastic material of rubber, also these materials are certified for food usage.

This turret is composed by a main shaft, that supports a complete mechanism (carrousel).

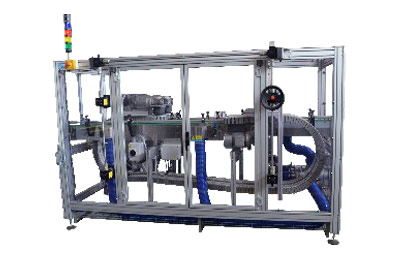

Before the containers are transported to the filling machine, Lanfranchi Linear Air Rinseris capable of blowing a strong 3μ clean air jet into empty containers (jars, bottles, cans).

Completely built in AISI 304 stainless steel, the machine is suitable for handling empty containers with a diameter that can vary from 40mm up to 155mm without replacing any additional parts or tools.

YOUR ENQUIRY

Please use this form to enquire further information:

Boxes are adopted mainly when you have to store various formats of containers that differ in shape, or, although they have the same shape, vary in colour or label. The easiest, most effective, flexible and safest way to store the quantities of containers required in a “just in time” manner is the Lanfranchi box system. The containers are available in various sizes and capacities up to a maximum of 10 m3 and can be stacked and transported by truck.

It is mainly used as dynamic storage in palletising and filling lines, or in extrusion lines.

It is also used when in an installation with a preform press connected directly to a blow moulding machine it is necessary to reduce the temperature of the preforms in order to make the heating and blow moulding process as homogeneous as possible.

The name itself identifies the result that is intended to be achieved with the creation of this new dynamic storage system, which enriches and completes the range of traditional systems.

The main characteristics of the Gentle Bottle Silo are:

Lanfranchi Ultraclean Silos are the ideal solution if you need a protective buffer for your blow moulding machine and you want to be sure that the bacterial load of the bottles does not increase while they are stored inside the silo.

Lanfranchi Ultraclean Silos was built entirely with AISI 304 stainless steel, it does not feature any point of retention, it is equipped with a CIP system and is guaranteed Class 100.

Conditioned type of panel silos developed specifically to fulfil the storage needs of the milk sector, where containers are made with HDPE and are completely closed.

The main problem with handling this type of container is controlling the inside temperature of the silo, to avoid phenomena of implosion or explosion of the container.

The problem was resolved by developing a silo system with a precise division of the air at different temperatures based on the position of the container inside the silo.

Temperature control is guaranteed through the use of insulating sandwich panels to create the silo roof, side walls and hopper.

The Silos Fast storage system has been created to be used as buffer for water and soft drink lines, but it can also be used for major storage. This product incorporates three fundamental elements:

Lanfranchi conveyor belts for bundles and cases are built based on what product needs to be handled. The robust main structure of the conveyor belt is stainless steel.

According to the characteristics of the product being handled, Lanfranchi offers a broad range of accumulation tables. The design takes into account system needs and Customer specifications. The following types of accumulation tables are available:

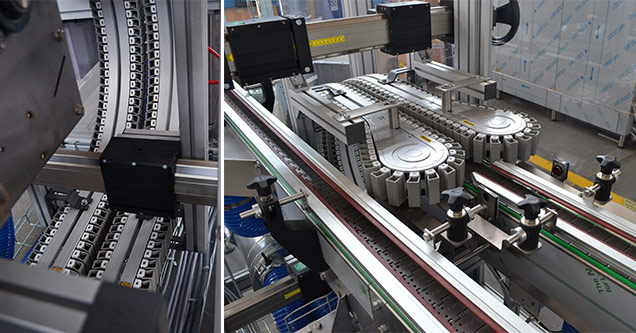

Lanfranchi table-top conveyor belts are designed for high speed handling of all types of containers with maximum accuracy. The flexibility required for creating the layout of more complex lines is made possible by the concept of modularity, that Lanfranchi table -top conveyor belts are conceived and built with. This modularity allows for quick installation. With the Lanfranchi modular concept, integration into existing lines comes naturally.

Thanks to the elevator or lowerator, the containers are conveyed with considerable changes in height, reducing the footprint to a minimum. According to the physical and morphological nature of the containers, Lanfranchi offers a broad range of elevators and lowerators:

For every type of application, thanks to their specialised multi-year experience the Lanfranchi team and offer the best solution.

Our bulk conveyors have been developed in order to reach the excellence in the handling of the containers and are destined to handling of the containers before the unscrambler.

Automation has also been optimised for this type of conveyor.

For many people, a bulk conveyor belt is just a coarse conveyor.

For Lanfranchi is a fundamental element of the lines of its Customers.

The structure of the conveyor belts and the possibility of combining covers, make Lanfranchi belts particularly “clean”. Even the hoppers, which are designed to optimise container handling, can be covered. The edges of the conveyor can be opened for easy access inside the conveyor belt and thereby simplify cleaning and special maintenance activities.

The Lanfranchi range of products for the handling of empty plastic containers also includes conveyor belts with suction and without suction. The main advantages of Lanfranchi conveyor belts are:

The belt vacuum units are completed with a wide range of accessories with which it is possible, for example, to obtain divisions from one to several rows or to increase the cleanliness features of the conveyor. Also for this type of conveyor, automation has been greatly refined so that, for example, the vacuum levels can be set and checked according to the different sizes to be processed. Both the conveyor belt frame and the vacuum chamber underneath are made of stainless steel.

Various types of conveyor belt covering are available: from the upper dust cover to a complete casing.

The suction fan is housed inside soundproofed casing. By using the butterfly valves inserted in the connections between vacuum chamber and conveyor belt, zones with different vacuum levels can be defined, such as in the collection tracts, for example. All the components of the table-top conveyor belts (alongside conveyor sections, the bends and the separators) are also available for the vacuum conveyor belts.

The chains of the vacuum conveyor belt are perforated according to the type of container being handled.

Lanfranchi is able to transport PET or HDPE bottles at high speeds ensuring high efficiencies. All the components (curves, assemblies, dividers, etc.) have been designed with the aim of maximising the efficiency of the line.

The Lanfranchi air conveyor belt is available in three versions:

Recommended for soft drinks, edible oil and detergents. i.e. for transporting products that require a basic degree of air filtration.

Recommended for water, juices and any other application for which the air that comes into contact with the bottle neck is treated with higher grade of filtration than the Basic version.

The possibility of an increased bacterial load inside the containers is eliminated. A special system for air recirculation allows to recover and filter the air over and over helping to extend drastically the life of the filters.

The levels of filtration that can be supplied are three:

Lanfranchi pneumatic conveyor systems are robust and provide efficient results in handling empty plastic containers of different types: from PP to HDPE. Pneumatic conveyor systems are made of steel but the PVC tube version is also available which requires low maintenance.

LARGE PIPE

This product carries containers or rejects for long distances effectively and efficiently. The containers move through the pipe without hitting each other, thereby guaranteeing container integrity. The large diameter pipe can be installed externally, offering simple and effective logistic solutions. The minimum power installed refers to the distances that can be covered with a single fan.

SQUARE MODULAR TUBE

This rectangular transport system is designed for plastic containers of any sector. Thanks to the finger-joint system, with modules that can be easily disassembled, there is the possibility of obtaining different things, for example:

• Possible chutes and hoppers for start and end of line

• Visual inspection mirrors

• Any kind of special accessories, such as hatches on bends for inspection or maintenance without disassembly.

PNEUMATIC BOTTLE CONVEYOR

This version of pneumatic conveyor uses pipes with smaller diameters compared to the previous version. The system allows the insertion of flow dividers up to six lanes, offering the customer greater flexibility of use.

Lanfranchi has introduced a new update available for all its unscrambler models to respond to the continuous lightening of PET bottles. Lightweight PET bottles bounce around more and are harder to control.

But now, thanks to the Vacuum Sliding Plate system, the Lanfranchi Unscrambler is ready to compensate for this instability by drastically reducing bottle jumps and keeping the speed of the unscrambler high.

The vacuum sliding plate quickly stabilizes a bottle inside the cradle and keeps the bottle in the ideal position for the following step of controlled drop through the funnel ending with the bottle standing up and ready to exit the unscrambler.

So, among the positive aspects of this upgrade is the increase in efficiency in the reordering process with more bottles correctly positioned within the funnels during rotation.

Our customers require a solution for stocking lightweight bottles, such as PET, PE, PP or HDPE, so Lanfranchi has designed a new system to reduce the load inside the silo. This new system can also be installed on existing silos such as FAST silo, Ultra-Clean, etc. and purchased as an upgrade.

The main concept of this application is to distribute and reduce the pressure of the bottles placed in the upper part of the silo compared to those in the lower part. It consists of a continuous series of inclined panels that are inserted inside the silo, dividing it into areas, the first effect of which is a uniform distribution of loads over the entire length of the silos (horizontal loads during the emptying operation).

Another important result is that these continuous baffles also reduce vertical loads. Thanks to their inclination, the load of bottles placed at the top does not have an impact on the load of bottles placed at the bottom.

With the Aspirated Star-wheel your bottles will not suffer a single scratch and you will no longer have to replace stars at every format change and have excessive encumbrance. If the range of bottles to be processed is very wide, the Vacuum Star-wheel is equipped with interchangeable and removable inserts. In most cases, two sets are more than sufficient to cover the entire range of bottles. The inserts are easily and manually applied. The vacuum itself and a mechanical interface, calculated at the design stage, keep these inserts in their positions.

How the Vacuum Star-wheel is being installed:

The upgrade consists of a pre-assembled unit that will allow easy installation on site. The old machine substructure will be dismantled on site (except for the lexan guards, which will be reused) and then the new pre-assembled unit will be installed, which will consist of the new substructure, the vacuum chamber, the vacuum star-wheel and then the fan complete with motor.

Thanks to Click Clack the Lanfranchi Unscrambler becomes even more flexible, practical and user-friendly. You can change the format of your bottles with a simple click!

MAIN ADVANTAGES:

It is not necessary to dismount parts: thanks to a hidden spring, you just need to raise or lower the lifter’s block with a click.

Thanks to the removal of the polyethylene blocks to be dismounted and reassembled, with a simple click-clack on the lifters it is possible to significantly reduce the operational process needed for each changeover.

By using Click Clack Lifters, it is possible to eliminate stock of pieces needed for the changeover.

The parts needed for the changeover leave the facility already installed on the machine and tested, reducing the possibility of errors due to the mixing of the parts.

System for reduction of compressed air consumption in unscramblers.

The new BFS system has the function of removing bottles in excess and misplaced inside the puckets.

The system is composed of fans ( from 2 to 8, depending on the model of the machine), which have an installed power of 0.85 Kw.

The main advantages of the BFS are:

The system can be used, on request, with the integration of filters, to create a slight overpressure of clean air, inside the machine.

The system is available to upgrade existing lines, even those not supplied by Lanfranchi.

This Upgrade can be installed on both table-top and air conveyor systems.

The micromotor used to move the side guides consists of a compact unit that includes:

The motor powers a threaded rod that is connected to the side guide.

The length of the rod can be varied according to need, so this system is truly ‘infinity’.

These motors were tested at Lanfranchi for months, having them changed thousands of times a day to check their reliability, and the component worked flawlessly.

The micromotor that controls the vertical movement is attached to the C-channel and to the bracket on which the other micromotor is mounted.

Since the lower micromotor must move up and down, the bracket is connected to a linear guide fixed to the side of the C-channel.

The system is available to upgrade existing lines, even those not supplied by Lanfranchi.

With LACO, the changeover is quick.

The LACO concept is based on the very simple ‘release, slide and lock-in’ formula in which the operator moves the lower part of the funnel into mechanical positions that are clearly marked; the cradle requires only a tool-free replacement of a separator according to bottle size. In the faster models of unscramblers with separators, the standard use of the vacuum star-wheel and the LACO design may eliminate the need to replace separators.

The format change operation is easily taken care of by a single unskilled operator and according to the machine model and bottle characteristics can range from 5 minutes up to a maximum of 30 minutes.

Laco funnels, with predetermined manual adjustment, process all sizes of bottles and do not require changing parts. Adjustment of the new Laco funnel is done simply by moving the knob to the position indicated for the bottle format to be processed, thus avoiding operator errors.