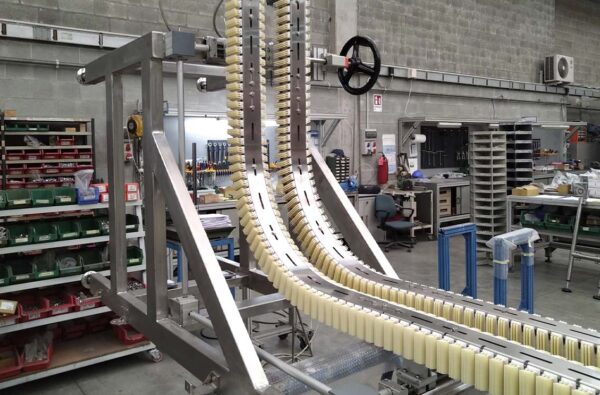

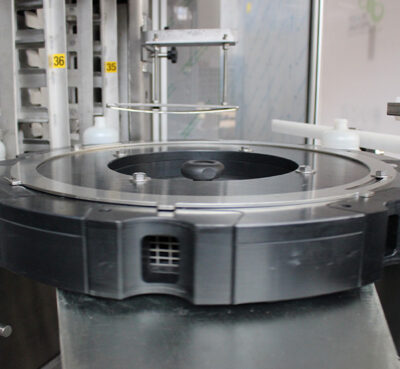

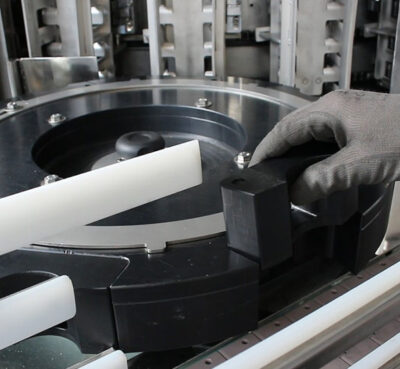

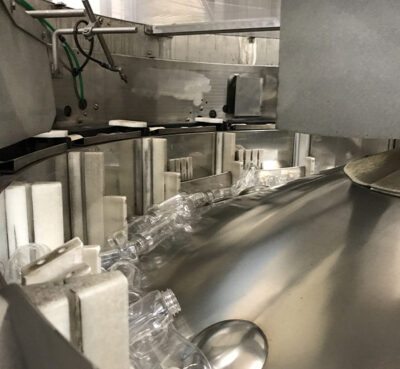

The belt vacuum units are completed with a wide range of accessories with which it is possible, for example, to obtain divisions from one to several rows or to increase the cleanliness features of the conveyor. Also for this type of conveyor, automation has been greatly refined so that, for example, the vacuum levels can be set and checked according to the different sizes to be processed. Both the conveyor belt frame and the vacuum chamber underneath are made of stainless steel.

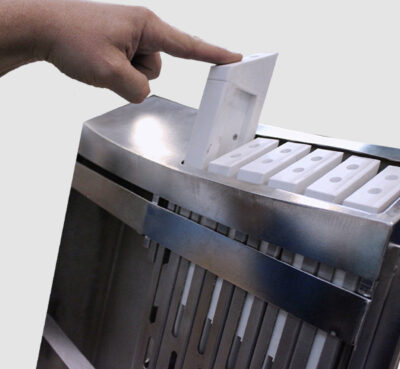

Various types of conveyor belt covering are available: from the upper dust cover to a complete casing.

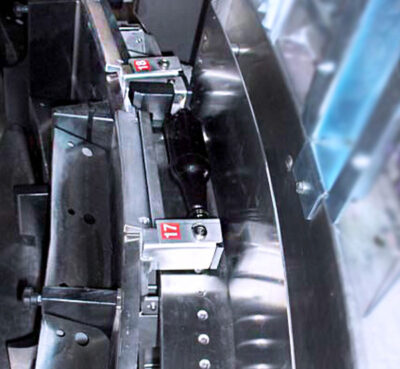

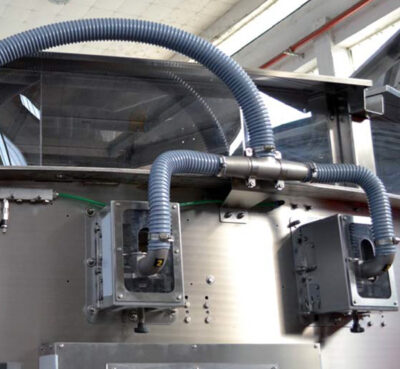

The suction fan is housed inside soundproofed casing. By using the butterfly valves inserted in the connections between vacuum chamber and conveyor belt, zones with different vacuum levels can be defined, such as in the collection tracts, for example. All the components of the table-top conveyor belts (alongside conveyor sections, the bends and the separators) are also available for the vacuum conveyor belts.

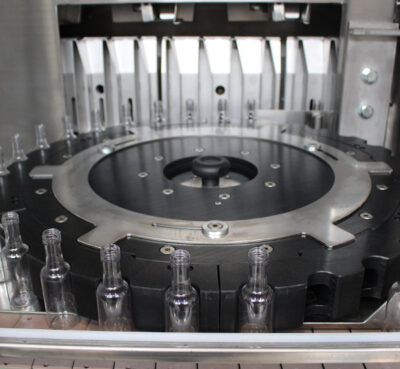

The chains of the vacuum conveyor belt are perforated according to the type of container being handled.