Click Clack Lifter – Change over has never been easier

HOW MUCH TIME DO YOU SPEND TO CARRY ON A CHANGE OVER?

- No tools needed

- Reduced time for change over operations

- No stock needed

- Reduced errors during change over operations

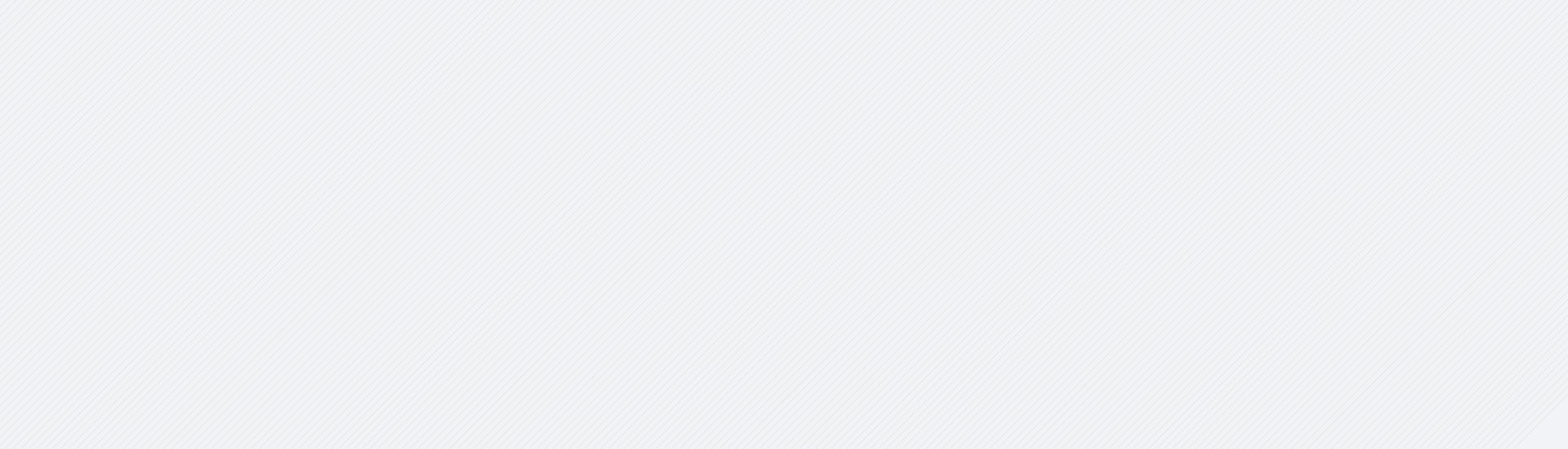

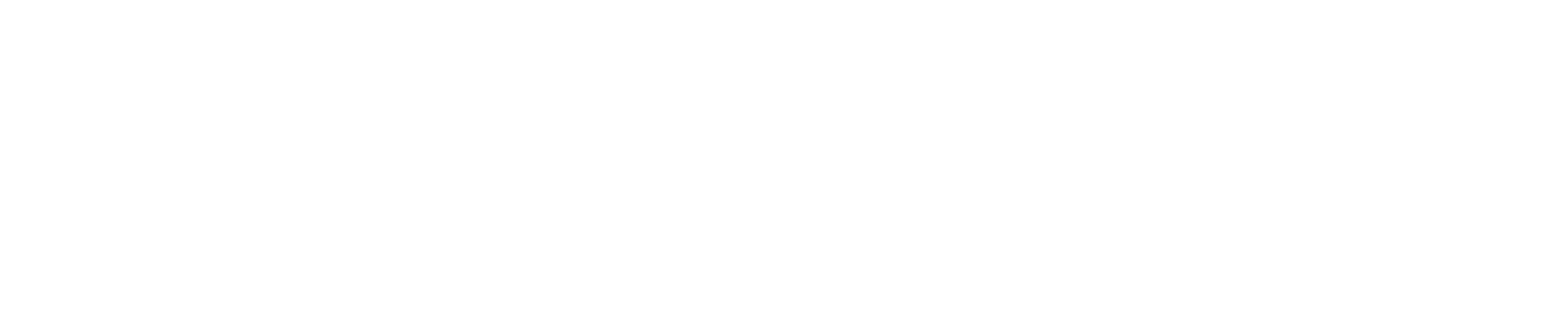

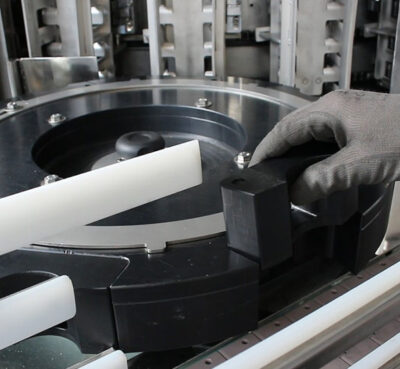

Standard Lifters:

Currently, with our standard Lifters, the operator disassembles and reassembles polyethylene blocks at every change over.

Each block of polyethylene corresponds to a bottle size. More bottle sizes you work, more parts you have to manage and stock in the plant.

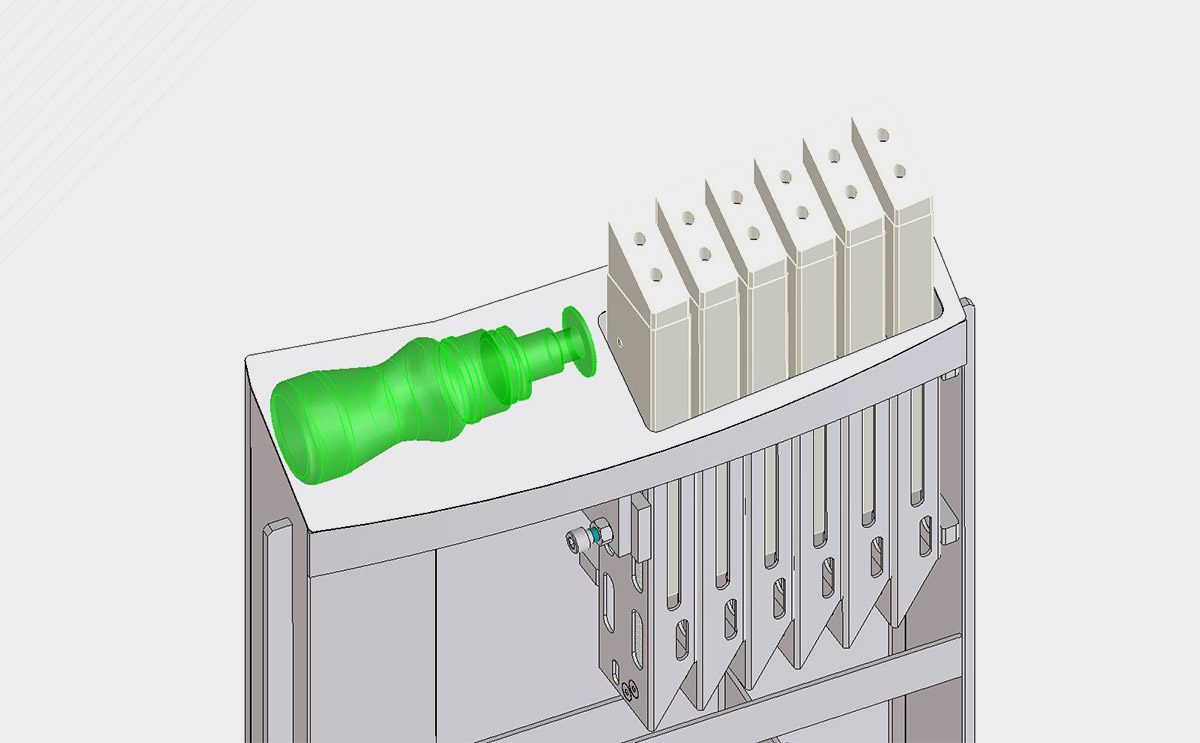

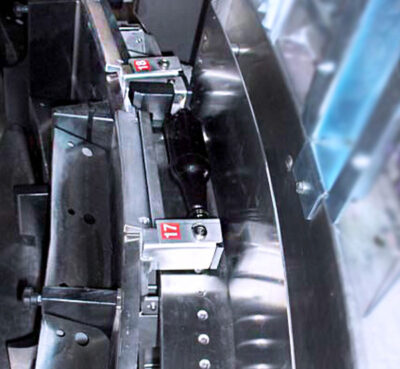

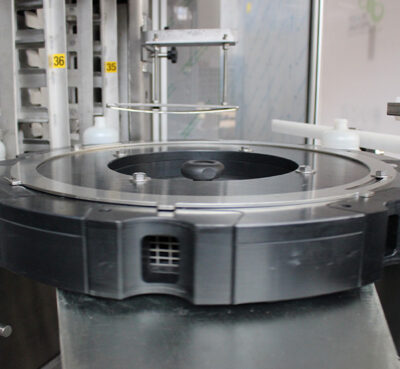

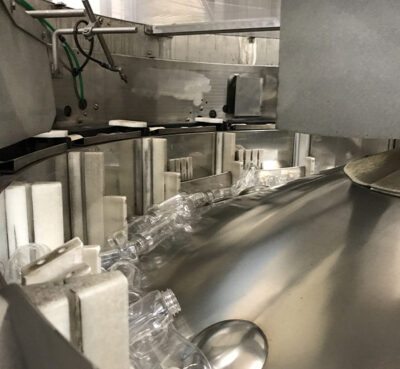

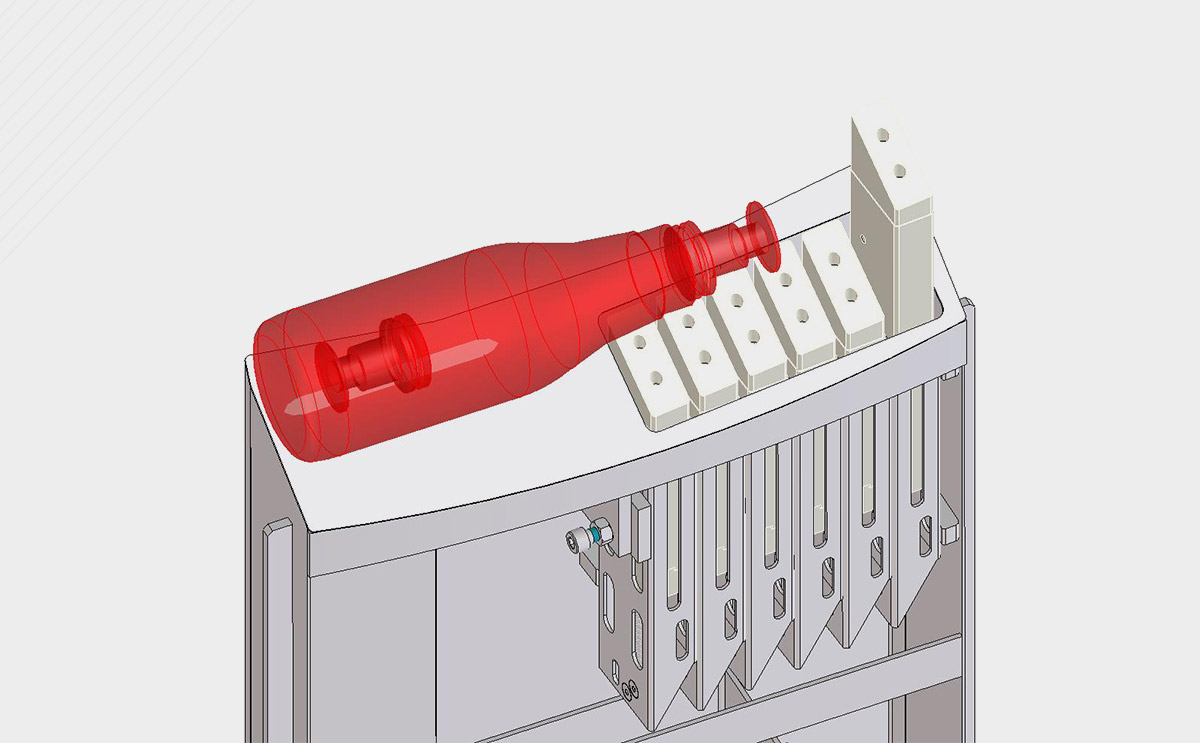

Thanks to the Click Clack Lifters, Lanfranchi Unscrambler becomes even more flexible, practical and user- friendly.

Change the format WITH A CLICK!

Main advantages

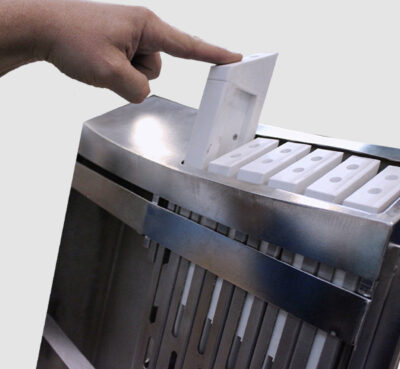

- No tools needed

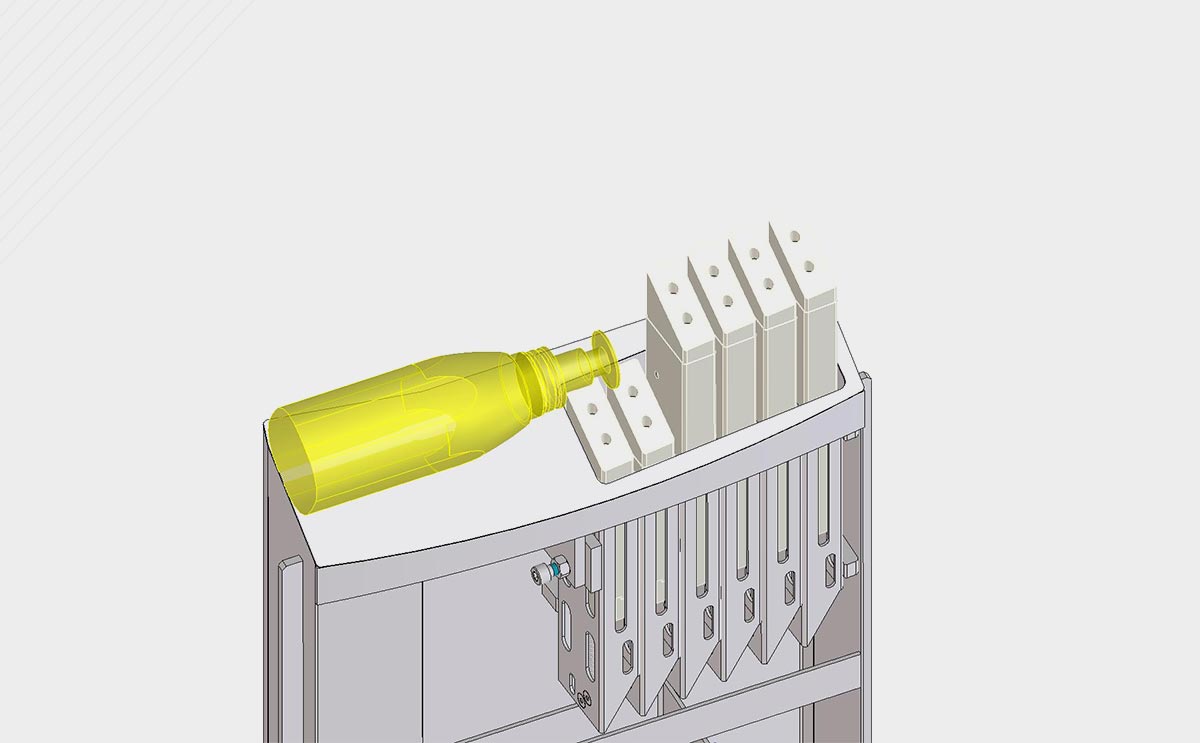

It is not necessary to dismount parts: thanks to an hidden spring, you just need to raise or lower the lifter’s blocks with a click. - Reduced time for change over operations

Thanks to the removal of the polyethylene blocks to be dismounted and reassembled, with a simple click- clack on the lifters it is possible to significatnly reduce the operational process needed for each change over. - No stock needed

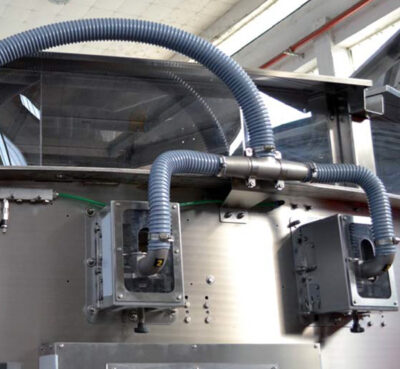

By using Click Clack Lifters, it is possible to eliminate stock of pieces needed for the change over - Reduced errors during change over operations

The parts needed for the change over leave the facility already installed on the machine and thested, reducing the possibility of errors due to the mixing of the parts.